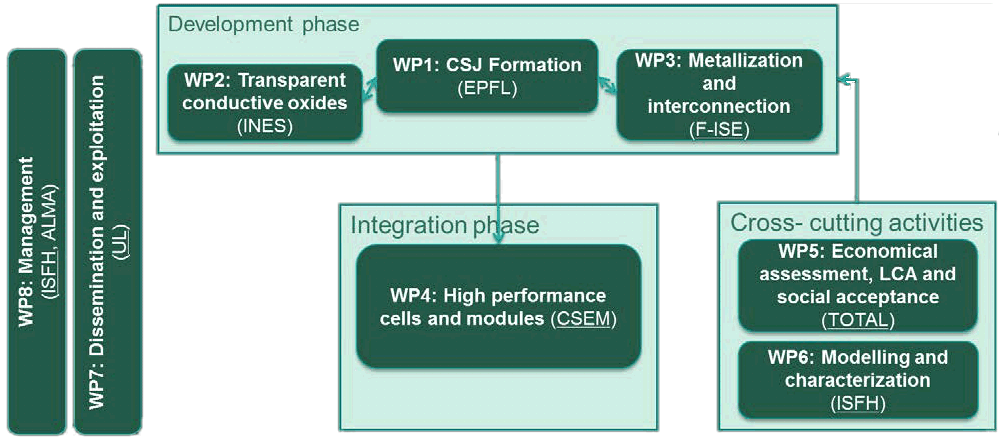

DISC project work packages

WP1, 2 and 3 deal with the development of the carrier-selective junctions, of transparent conductive oxides, and of the metallization, respectively. Essentially all of the relevant material properties such as transparency of single layers, passivation quality and current transport properties of CSJ/TCO stacks, contact resistances and line conductivities of the metallization, can be investigated on appropriated test structures. Different types of carrier selective junctions (in combination with appropriated TCOs) and different metallization schemes will be investigated. Regarding the former, CSJs based on doped thin Si layers are competing with CSJs based on transparent metal compounds. Regarding the latter, Cu plating is compared with screen print metallization using highly conductive high-temperature metal pastes. This variety of the different approaches implies a significant reduction of the risk that the project objectives are not achieved.

The best solutions development in WP1, 2 and 3 will be implemented into solar cell prototypes in WP4. Here, two competing approaches are evaluated: a process sequence based on hightemperature stable CSJs, and a process sequence based on CSJs formed by transparent metal compounds with a so far unknown temperature stability. Single-cell modules will be fabricated in order to facilitate accelerated aging tests for an assessment of the reliability of the cell components. From the cells fabricated in WP4, highly efficient modules will be fabricated also in WP4. The cell and module development will be guided by advanced optical and electrical simulations performed in WP6. The required input parameters will be obtained by a detailed characterization of all essential cell components.

The technical work packages will be accompanied with an economic, environmental and social assessment in WP5. The economical assessment will be based on cost-of-ownership data from the equipment manufactures and on specific process sequence, and will result in a calculation of the costs per kilowatt at module level. The environmental and social assessment includes life cycle assessment of the improved PV modules in order to address the sustainabiltiy impact of the project as well as recycling aspects, and an assessment of possible issues regarding social acceptance of the developed technologies.

As further crosslinking activity, the dissemination and exploitation of the results will be addressed in WP7. The management of the project, i.e., the assurance of a smooth collaboration and integration of all partners, the application of personalised methodologies and tools for efficient implementation of activities, as well as decision making and steering, the assurance of timely reporting and communication with the project officer and the EC, will be performed within WP8.